Microfibres Technologies utilizes modern processing equipment to cut, grind, mill and pulverize numerous types of materials from 180 microns and up to provide our customers our trademark TitanBlu®, HydroWhite® & QuickWick®. Our proprietary processing equipment is capable from 3,000 lbs. per hour to 200 lbs. per hour dependent on cut size. Each processing line is equipped with multiple magnets / metal quality detection handling equipment to assure product is free from all contaminants.

Microfibres Technologies precision cut capabilities are from 3mm on up on continuous filament form or in tow form. Our processing of precision cut fibers outflows thru sifting equipment specifically sized to meet our customer requirements and to assure quality standards is met.

We process Cotton, Cotton blends, Acrylic, Nylon, Polyester and Polypropylene, Nylon RFL, Polyester, RFL, Kevlar, Nomex, Technora, Twaron, Burlap, Cellulose, Corn Stover, Cotton Seed, Sisal, Jute and other proprietary fibers specific to our customer’s specifications.

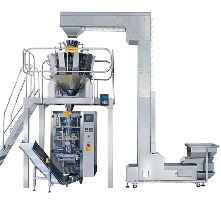

Our semi-automatic bagging equipment provides accurate pre-weighed bags of flock and powders or precision cut fibers in a variety of bag sizes from 3 pounds to 40 pounds and various types to meet customer requirements. Pre weighed EVA bags provides huge benefit to our customers, enabling them to precisely load their formulations with pre weighed bags while improving production efficiency and reducing process waste.

Bulk Bagging packaging is available in Polyethylene, Paper Bags, Super Sacks, Bulk Boxes (Gaylords) ranging in weight from 10 lbs. to 650 lbs.

Baled packaging is available on certain products and range from 500 lbs. to 840 lbs. per bale.

Microfibres Technologies is driving quality and performance into all aspects of our business by fully implementing Lean and Six Sigma methodologies integrated with the our PPO platform to provide continuous improvement culture. We have adopted and deployed quality principals and tools, such as Safety Awareness – CMAE 1514 and Quality Practice – CMAE 1522 training and certifications to accelerate our business performance. Continuing our commitment for improvement, in 2017 Microfibres Technologies will become ISO 9001 – ISO 2017-1 certified.

Microfibres Technologies is equipped with a state of the art laboratory to provide technical assistance and testing to meet customer requirements. We provide the following types of testing: sifting test, moisture retention, abrasion testing, bulk and fiber length.

Microfibres Technologies will provide the timely delivery of products whose performance and appearance are in accordance with our tradition of high manufacturing standards, and to support our customers by providing superior products and services of exceptional value which help them gain competitive advantage

in their markets.